Sapperton Tunnel

Picture Gallery

Back

to T&S Canal Index

The biggest single engineering work,

and the most daring, on the Thames & Severn Canal was Sapperton Tunnel.

Its total length was 3817 yards, about 2 1/4 miles (3.5Km) , and at the

time of its construction it was the longest tunnel ever built (excluding

mines and conduits). Not only was its length ground breaking; its bore of

15ft was much bigger than its predecessors which were built to accommodate

7ft beam narrowboats.

The tunnel had to be built level (a slope of 1 in 11,000 would have meant

that there would have been a foot less water at one end compared with the

other!) and it was straight enough to see right through (so long as you

were on the right side of the entrance).

Built in a little over 5 years, it ranks as one of the engineering wonders

of its age and begs the question as to why Box Tunnel built by Brunel 52

years later, and shorter by more than 500m , receives such attention.

The method of construction was to mark out the line of the tunnel

on the surface and sink 24 shafts. These were then linked up creating a

headway which could then be opened out to the full bore. Gunpowder was extensively

used in the sections of the tunnel which passed through rock.

The method of construction was to mark out the line of the tunnel

on the surface and sink 24 shafts. These were then linked up creating a

headway which could then be opened out to the full bore. Gunpowder was extensively

used in the sections of the tunnel which passed through rock.

Once the tunnel was complete, the

shafts were capped at the top and arches built where there would otherwise

have been nothing in the unlined lengths covered the bottom.

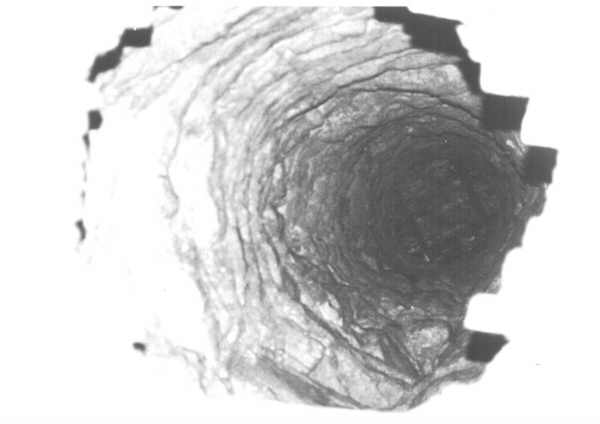

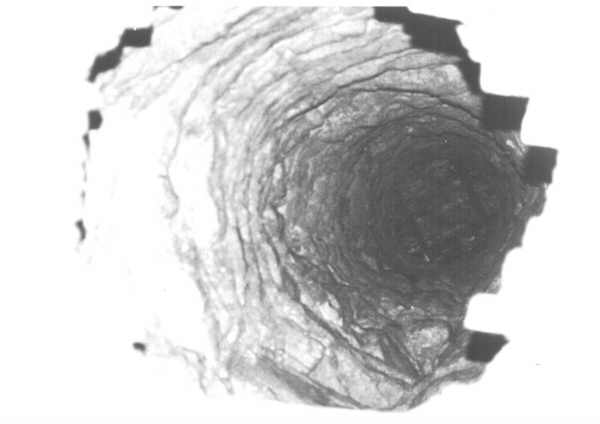

Just over half of the tunnel

is in rock and in many places this was solid enough not to require any lining

but fissures in the rock made keeping the canal watertight a challenge.

Where the rock was less solid, the tunnel was lined in brick or stone. Long

lengths have stone walling on the sides but the roof is unlined and often

in the form of a natural flat slab.

Just over half of the tunnel

is in rock and in many places this was solid enough not to require any lining

but fissures in the rock made keeping the canal watertight a challenge.

Where the rock was less solid, the tunnel was lined in brick or stone. Long

lengths have stone walling on the sides but the roof is unlined and often

in the form of a natural flat slab.

The remainder was through fullers

earth, a substance that expands in volume dramatically when it becomes wet,

and these lengths were lined throughout, usually in brick. There are a couple

of lengths where the nature of the fullers earth seems to have been particularly

problematic. These occur near the Daneway end where there is a complete

obstruction where the tunnel has collapsed and again near the centre where

side wall and roof falls have occurred although it is possible to climb over

these. In these two areas, parts of the tunnel walling, although still standing,

have been distorted to an alarming degree.

The 1976 Freeman Fox survey concluded

that two thirds of the tunnel appears to require little or no attention,

about a fifth will require some repair work and the remaining sixth will

need total reconstruction – not too bad for a tunnel which has received no

maintenance for almost 100 years.

In 2008 a survey established that

it was still possible to get about 2 miles into the canal from the

Coates end but this did involve crossing a series of side and roof

falls near the middle of the tunnel in the fuller earth section. Of the

3817 yards of tunnel, at least 500 yards will need relining in the two areas where the collapses have occurred.

The water levels in the the tunnel

today fluctuate significantly in response to ground water levels. The clay

canal bed in the limestone sections was very prone to rupture when ground

water levels were higher than that in the canal and the resultant holes

released water from the canal when the ground water fell to a lower level.

There are some powerful springs in the tunnel and at one point these have

been vented in pipes from under the canal bed to outlets above the canal

water level; even so, the pressure has been great enough to lift and break

the thick concrete bed at this point!

The

Cotswold Canals Trust used to run trip boats into the tunnel during the winter/spring

when water levels permitted but these are not possible at the moment.

The method of construction was to mark out the line of the tunnel

on the surface and sink 24 shafts. These were then linked up creating a

headway which could then be opened out to the full bore. Gunpowder was extensively

used in the sections of the tunnel which passed through rock.

The method of construction was to mark out the line of the tunnel

on the surface and sink 24 shafts. These were then linked up creating a

headway which could then be opened out to the full bore. Gunpowder was extensively

used in the sections of the tunnel which passed through rock. Just over half of the tunnel

is in rock and in many places this was solid enough not to require any lining

but fissures in the rock made keeping the canal watertight a challenge.

Where the rock was less solid, the tunnel was lined in brick or stone. Long

lengths have stone walling on the sides but the roof is unlined and often

in the form of a natural flat slab.

Just over half of the tunnel

is in rock and in many places this was solid enough not to require any lining

but fissures in the rock made keeping the canal watertight a challenge.

Where the rock was less solid, the tunnel was lined in brick or stone. Long

lengths have stone walling on the sides but the roof is unlined and often

in the form of a natural flat slab.